Tesla CEO Elon Musk is attempting to invest in Twitter and control a number of companies at the very same time.

James Glover II | Reuters

Tesla has shaken up leadership at the Gigafactory, its sprawling battery plant outside of Reno, Nevada, and is placing new aims for the facility.

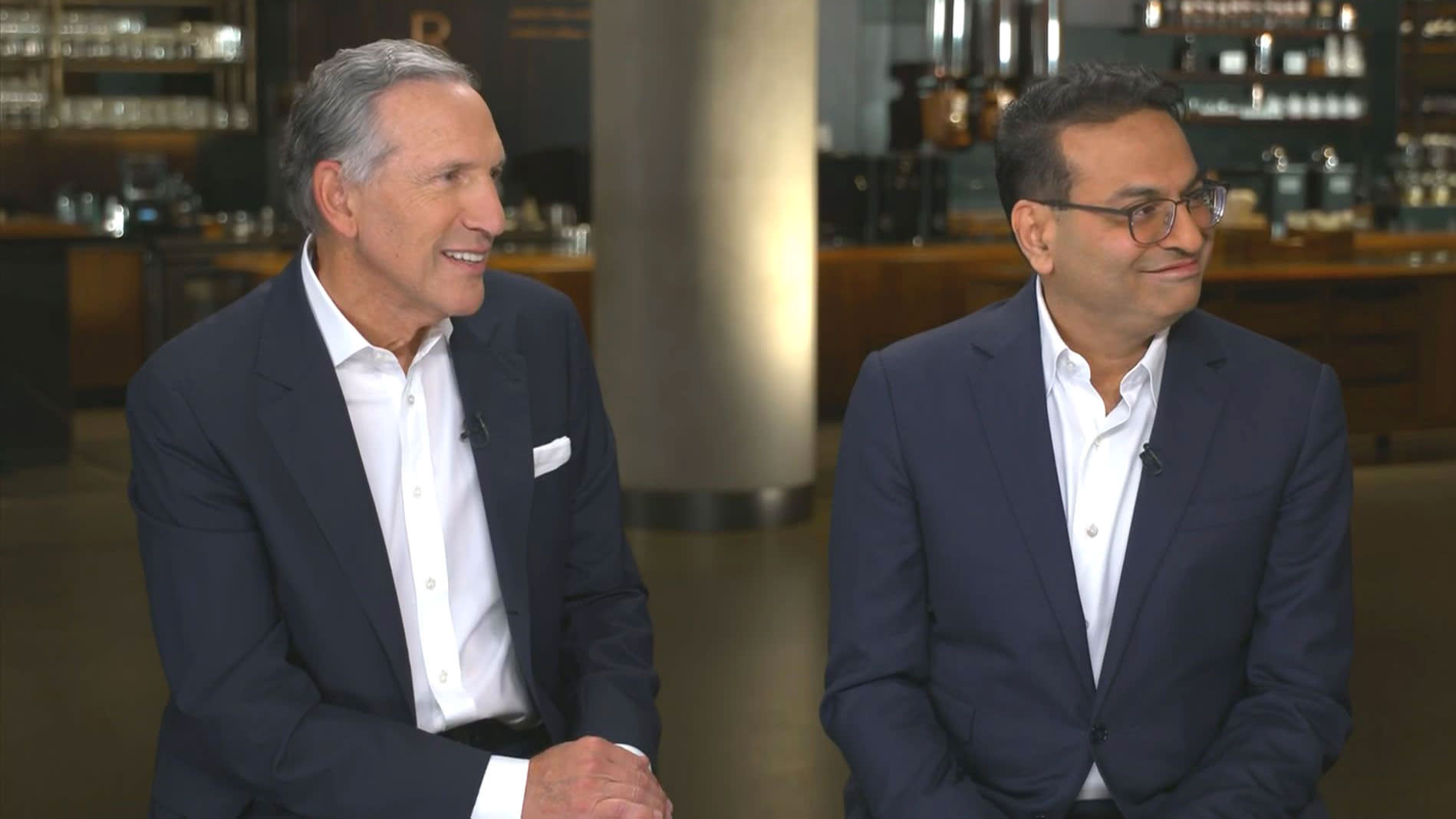

Former Vice President of Gigafactory Functions, Chris Lister, still left Elon Musk’s electric auto and clear vitality business enterprise this summer, and Hrushikesh “Hrushi” Sagar was promoted to oversee the Gigafactory, according to audio of a Thursday meeting and files shared with CNBC by individuals who get the job done at the factory. Sagar reports specifically to CEO Elon Musk and will also be overseeing Tesla’s automobile assembly plant in Fremont, California, simultaneously.

relevant investing news

Sagar spoke to a team of hundreds of Gigafactory workforce on Thursday afternoon about administration improvements, efficiency critiques, manufacturing facility milestones, and intense new ambitions for the facility. He also disclosed some info about progress in Tesla’s factories in Austin, Texas, and outside of Berlin, Germany.

Sagar briefly resolved Lister’s departure stating, “I seriously take pleasure in what Chris Lister did below, Chris’s contribution. I’m really thankful, like Elon, and Tesla is incredibly grateful, for his contribution, but at the very same time now we are relocating on to the upcoming stage.”

Personnel at the Gigafactory manufacture battery packs and electricity trains for Tesla’s electric vehicles, as very well as the massive backup batteries, Powerwall and Megapack, marketed by Tesla’s Energy division.

Through the assembly, Sagar celebrated the simple fact that Tesla manufactured around 134,000 automobiles in its Fremont, Calif., manufacturing unit in the 2nd quarter of 2022, and said that August was a person of the file months for Fremont in terms of creation. The Fremont factory is now in a position to make all around 12,000 automobiles for every week and is aiming for 14,000 for every 7 days as its future objective, he reported.

He also mentioned that Tesla’s crew in Brandenburg, Germany, a short while ago strike a milestone of being able to generate 1,000 cars and trucks on a rolling 7-working day foundation. Musk a short while ago frequented the German manufacturing unit and the organization expects it to ramp generation to make 5,000 vehicles per week by the conclusion of 2022. In the beginning, Reno was sending drive models to Germany to assist in that exertion.

Tesla’s new manufacturing unit in Austin, Texas also strike the 1,000-for each-week production fee.

In terms of push unit output, the Gigafactory created 283,473 energy trains in the second quarter of 2022 “feeding” the company’s Fremont and Austin factories.

“You all performed a pretty huge function,” Sagar reported. “I just want to say thank you from the base of my heart,” to the Reno crew.

New leaders and ambitions for the Gigafactory

Ahead of he joined Tesla in late 2017, Chris Lister invested 22 yrs in precision manufacturing roles at PepsiCo. During his tenure at Tesla, the Gigafactory skilled a immediate make-out and expanding pains including large volumes of scrap, fires and oil spills. But in ramping up creation there, he also served propel Tesla to grow to be the major-marketing battery electric powered car manufacturer in the U.S. and earth. Lister and Tesla did not quickly react to requests for remark.

Sagar’s new title, according to his LinkedIn profile, is senior director of auto functions and manufacturing engineering.

Sagar advised workers on Thursday that they should really believe of the Fremont manufacturing unit as their “purchaser,” noting that car or truck production there succeeds or is hampered relying on Gigafactory shipping volumes and excellent.

Though Sagar does not prepare to commit most of his time in Reno, he options to do the job closely with leaders at the plant, which includes Power Chief Matt Reddick, who joined the organization fewer than 6 months in the past, and Web-site Leader Eric Montgomery, who will regulate issues day-to-working day in Nevada. Other best leaders at the Gigafactory now involve Jeff Jackson, who is heading up infrastructure for the facility, and Bert Somsin, a human resources director for the plant.

At the exact meeting on Thursday, Montgomery explained to Gigafactory staff that they require to get to a continual output of 8,800 high voltage battery packs for every week to support Fremont’s new creation targets, and “optimize all-wheel-drive builds.” He mentioned August 2022 was also the Gigafactory’s second-best month on record for manufacturing, 2nd only to Oct 2021.

Reddick claimed Tesla can now deliver 42 large Megapack batteries in a 7-working day rolling time period. Megapacks are about the size of a delivery container and are employed for utility-scale electrical power storage, often to store surplus power created by wind or photo voltaic.

Tesla is on goal to create 442 Megapacks through the 3rd quarter of 2022, symbolizing an 85% progress above Megapack output in the earlier 3-month period.

The Gigafactory also strike and has exceeded a generation rate of 6,500 Powerwalls for every 7 days. Powerwalls are the smaller sized backup batteries for property use that CEO Elon Musk a short while ago promoted on Twitter amid a significant heatwave in California. The heat wave threatened blackouts, and had the point out urging residents to minimize their ability intake throughout peak several hours.

Tesla earlier essential customers who needed to purchase a Powerwall also to invest in a solar roof from the firm. The Nevada Gigafactory built 37,600 Powerwalls in the next quarter, Montgomery reported, and mentioned the facility is on concentrate on to raise that by 22% in the 3rd quarter.

In phrases of the facility itself, Jackson touted a new, state-of-the-art h2o remedy facility that Tesla is developing on web-site.

“This is to heading to eliminate the discharge of our internet site course of action h2o, or wastewater, and it’s likely to make it possible for for 98% drinking water recycling and evaporation,” he reported. “It is a huge detail, it is aligned with our mission.”

Jackson also gave an update on the Gigafactory’s photo voltaic roof. “Suitable now we’ve acquired about eight megawatts on the roof that we are ready to use on a day by day basis, which is actually enjoyable,” the power leader explained.

Tesla also has a new food stuff seller on website that presents poke bowls, is creating a meditation area for workers, and is producing road advancements and installing a lot more EV chargers along the roadways close to the facility.

On the human resources front, workers were being urged to cut down the number of labor several hours it can take to produce a one unit of the products they build in their teams, and to file far more “just take demand” notices about how to boost protection and lessen fees close to the plant.

The corporation is relocating previous steep headcount cuts that took location in the second-quarter this yr, and is in the midst of an considerable, functionality review system, Sagar stated.

A person employee questioned management if their fairness grants would be tied to firm milestones this year, and administration reported no. But human methods teams and administrators are nevertheless figuring out who could be qualified for promotions, raises and bonuses. Sagar mentioned by the finish of September, administrators should really be speaking with their groups about their efficiency assessments.

Staff questioned administration to go over irrespective of whether and wherever Tesla’s up coming manufacturing unit may well be built. Lobbying action by Tesla in Canada, and the firm’s investments up North earlier have stirred speculation of a Canada-centered plant.

Sagar explained, “I have some thought on the candidates but I do not feel I am at liberty right now to disclose these candidates due to the fact of the confidentiality about some of these factors.” He did offer you, “There is an thrilling long run for North The usa and all all-around the Americas.”