A robotic arm receives to do the job at German producer Rittal’s clever manufacturing facility in Haiger, to the west of Hesse, Germany.

Rittal

Conversational artificial intelligence that can be utilized to converse with machines and deliver equipment sections. Electronic variations of cars and planes that can be modified to great-tune their actual physical counterparts. And autonomous robots that transfer as you wander by.

These are just a several of the technologies that will electric power the factories of the long term, in accordance to technologists and sector specialists who spoke with CNBC.

In the future, factories will be substantially extra linked, relying on a blend of systems, from artificial intelligence, information platforms and edge units to the cloud, robotics and sensors, Goetz Erhardt, Europe direct for Accenture’s electronic engineering and manufacturing division, told CNBC.

“These technologies help thoroughly automated, ‘dark’ crops, automatic final decision-creating, increased gear monitoring, and new production networks with recycling and upcycling capabilities,” Erhardt said by way of e mail.

Present day factories — from these used in equipment and automobiles to foods processing vegetation — have progressively turn into much more state-of-the-art with regard to adopting technologies. Robotic arms concerned in the production procedure — incorporating and taking away resources, welding and placing items on pallets — are now a common sight.

Much more sophisticated A.I.

As considerably more state-of-the-art synthetic intelligence technologies are included into the mix, the industrial manufacturing procedure could shake up more. Conversational methods this sort of as OpenAI’s GPT could 1 working day turn out to be integrated into robotics, enabling far more refined, emotionally intelligent devices.

“Generative AI (AI that can make new content material in response to person inputs) has monumental prospective in manufacturing for tools optimization, interaction and intelligence — from robotic procedures via to machining,” Simon Floyd, director of manufacturing and transportation industries at Google Cloud, told CNBC.

Google is between the tech entire world giants seeking to capitalize on large language designs, which can create additional humanlike responses many thanks to the substantial amounts of information they are educated on. The company released its possess AI chatbot Bard previously this calendar year to rival OpenAI’s ChatGPT.

Client solutions usually are not the only aim of Google’s AI attempts. The firm a short while ago upgraded its cloud platform for manufacturers to far more successfully pull information from machines and detect anomalies in the manufacturing system.

Likely ahead, AI will be ready to “converse using purely natural language with production products to comprehend the present-day point out and the predicted upcoming efficiency — therefore helping men and women and allowing for them to aim on high benefit duties,” Google Cloud’s Floyd explained to CNBC.

Floyd claimed that Google is by now performing to reach this with normal language processing capabilities in its AI applications. The firm has also created a language model for robots named PaLM-E, which gathers sensory information from the bodily setting, as perfectly as text-based mostly inputs.

Engineers will ultimately be capable to develop new machinery using generative AI equipment, Floyd mentioned.

“In the potential, there is probable to deliver material from and for many styles of production machines, ranging from unique restore directions to program code that is tailored to a unique asset.”

‘Digital twins’

Just one progress lots of industrialists are psyched about is “electronic twins” — 3D digital replicas of objects in the bodily globe that can be modified and current in parallel with the things they aim to mimic.

A single example of a enterprise employing digital twins to support its bodily manufacturing is Rolls Royce, whose engineers generate specific virtual copies of its jet engines and then set up sensors and satellite networks on-board to feed again knowledge to the digital duplicate in genuine time.

“For every contemporary Rolls Royce jet motor up on a airplane in the sky, you will find a person in the cyber sphere that wants to be managed, performing out how significantly stress is heading as a result of the aircraft,” reported John Hill, CEO of Silico AI, a startup that focuses on digital twins for organization procedures. “That will count on how the engine is faring in the atmospheric situations and pressures in the air.”

An additional example is Renault, which developed a digital twin for a new “software program-defined” vehicle with artificial intelligence abilities to increase services.

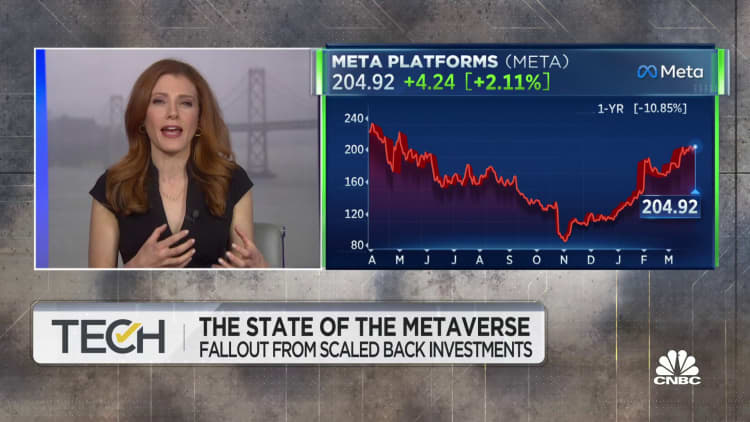

Digital twins kind portion of the so-named “metaverse,” which embodies the idea that people today will spend extra of their function and leisure time in huge 3D digital areas. Some providers are also seeking to include the actual physical planet in some iterations of the metaverse.

Lots of producers see potential in the “industrial metaverse,” a variation of the metaverse tailored to the manufacturing, development and engineering industries. Accenture’s Erhardt instructed CNBC that he is predominantly looking at use situations in imaginative collaboration and solution growth, servicing and distant repairs, building and optimizing creation operations, and workforce schooling

“The metaverse could turn out to be a sport changer for industrial providers after they few its collaborative, immersive, visual and intuitive proportions with digital twins fed by built-in facts pools across departments, programs, functions engineering and IT,” Erhardt mentioned. “This could produce a virtual, thoroughly immersive and intuitive simulation of the complete enterprise.”

Protection first

Companies are searching for techniques to slash down on more menial duties in factories with digital know-how, amid a wave of labor shortages.

“Formerly, automation has not been an possibility for producing products because of to small monetary sources and investment decision,” Olivier Ribet, Govt Vice President, EMEAR at Dassault Systèmes, instructed CNBC.

“On the other hand, this is transforming rapidly due to technological variations that have lessened charges and democratized automation by low/no code robotics allowing for additional producing providers to leverage the rewards of automation in phrases of precision, effectiveness, and efficiency.”

There are downsides to consider — not minimum of which position protection — as the rise of AI and electronic automation in factories has led to problems about the labor market. Generative AI, a reasonably the latest development, could erase 300 million positions, Goldman Sachs estimates.

Nevertheless, record shows that technological development won’t just make work opportunities redundant, it also creates new roles— which normally outpaces the range of careers displaced. Brands are even now scrambling for staff, with 41% of producing firms citing expertise pool as a “quite important” barrier stopping whole opportunity, in accordance to a Bain and Company survey.

The hope is that connecting equipment to the online and integrating sensors and predictive AI algorithms will allow them to additional safely navigate their environment and perform collaboratively with people, somewhat than substitute them, according to Maya Pindeus, CEO of AI startup Humanising Autonomy.

“Believe of the factory, you have robot arms, you have distinctive automobiles to move merchandise close to, you have operators, you have protection cameras,” Pindeus told CNBC.

“What I would search at in the factory of the foreseeable future is you have significant stages of secure automation that can function close to people … I’ve been to factories where by you have the major robot arm caged up and it can be really much away from people today. It seems really inefficient to me.”