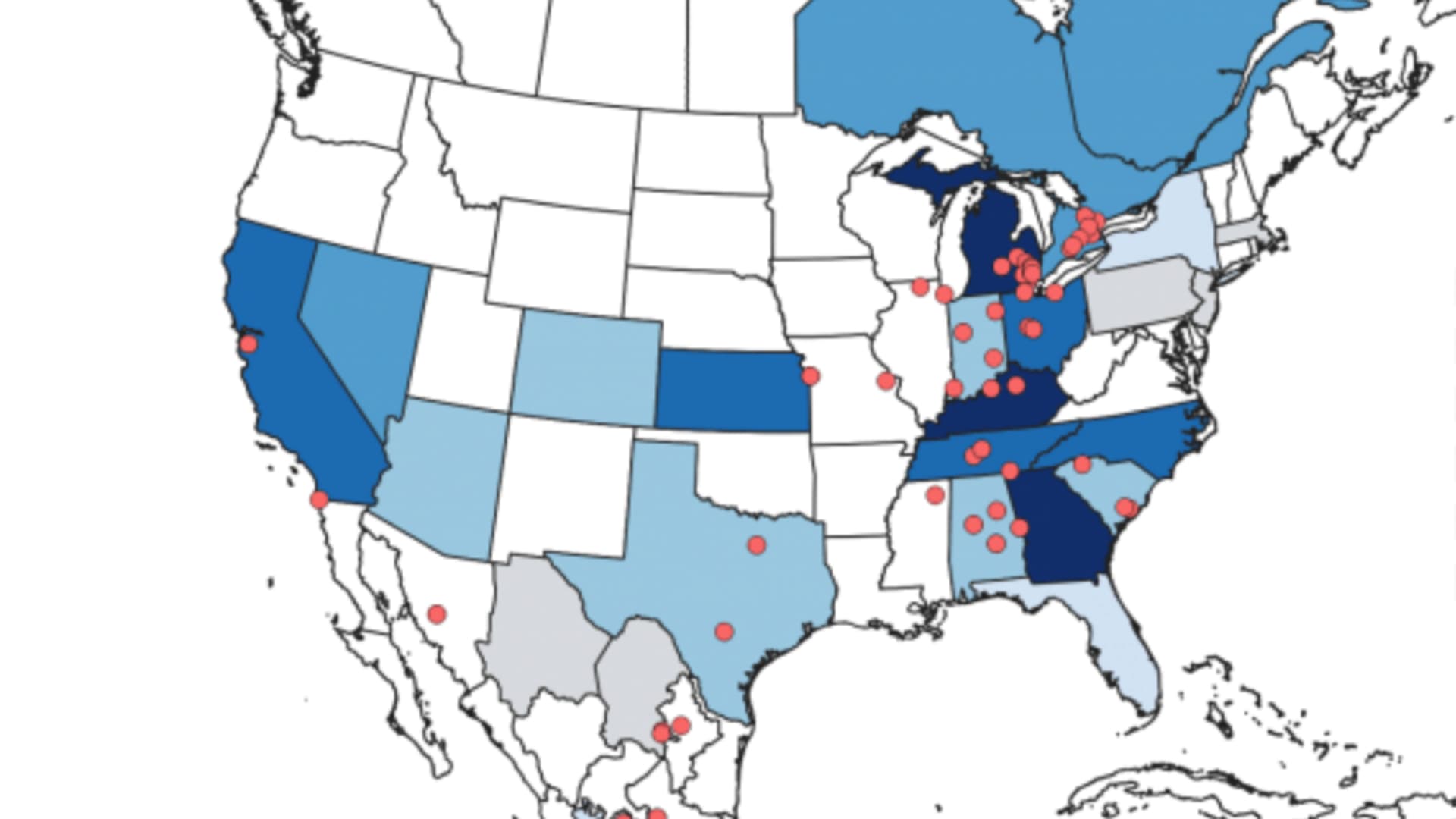

Planned electric motor vehicle battery plant capability in North America by 2030. Data current via November.

U.S. Division of Strength, Argonne Nationwide Lab

Ga, Kentucky and Michigan are likely to dominate electric powered auto battery manufacturing in the United States by 2030.

Each and every of those people three states will be able to manufacture among 97 and 136 gigawatt hours’ value of EV batteries for each year by 2030, in accordance to ideas they have laid out.

Kansas, North Carolina, Ohio and Tennessee will also be key gamers, with planned potential for between 46 and 97 gigawatt hours’ of EV battery creation for each 12 months by 2030.

This prepared manufacturing potential was highlighted by the U.S. Section of Energy on Monday, dependent on a November 2022 report from the Argonne Nationwide Laboratory in November.

To hold up with escalating demand from customers for EVs, the complete construct out of EV battery manufacturing ability in North America will go from from 55 gigawatt-several hours per year in 2021 to pretty much 1,000 gigawatt-hours for every yr by 2030. So significantly, the planned investment in these factories is much more than $40 billion, in accordance to an October report from the Federal Reserve Lender of Dallas.

The Ford Motor Co. and SK Innovation Co. electrical vehicle and battery production advanced beneath design in close proximity to Stanton, Tennessee, on Tuesday, Sept. 20, 2022.

Houston Cofield | Bloomberg | Getty Pictures

By 2030, this EV battery production ability will help the producing of between 10 million and 13 million all-electric autos for each year, putting the U.S. in position to be a international EV competitor.

“Escalating battery producing potential by far more than 15x by 2030 will place the U.S. in the leadership circle of the EV market,” Nick Nigro, founder of the public policy store, Atlas General public Plan, explained to CNBC.

“This ability will present more than more than enough batteries for the U.S. to reach the Biden Administration’s intention of 50% EV sales by 2030,” Nigro explained to CNBC. The function Atlas does features equally transportation and local weather policy.

The planned wave of EV battery manufacturing plants will be close to EV assembly services in North The united states, discovered by purple dots in the graphic.

“It really seems that they are making an attempt to reduce their all round production expenses in this article,” David Gohlke, a single of the authors on the paper from Argonne, advised CNBC. “They have these somewhat significant batteries that they have to have to ship from the assembled battery assembly place to their automotive assembly plant, and they will need to make absolutely sure that they have the infrastructure all-around to do that.”

Almost all of the planned vegetation in Argonne’s report will make lithium ion batteries and will be joint ventures in between automakers and battery manufacturers like Panasonic, Samsung, LG Chem or SK Innovation, Gohlke told CNBC.

Going forward, it will also be important to teach staff and ramp up the supply chains of vital minerals, Nigro instructed CNBC.

“The big obstacle for the business will be establishing a responsible provide chain and building the human ability to make these factories hum,” Nigro informed CNBC.